Fasteners and Machining: Incorporating Accuracy and Strength in Manufacturing

Fasteners and Machining: Incorporating Accuracy and Strength in Manufacturing

Blog Article

Browsing the World of Fasteners and Machining: Methods for Precision and Speed

In the intricate realm of bolts and machining, the mission for accuracy and speed is a continuous challenge that demands thorough attention to detail and critical planning. From recognizing the diverse variety of bolt types to choosing optimum products that can endure rigorous demands, each action in the process plays an essential duty in achieving the preferred outcome. Accuracy machining methods further raise the complexity of this craft, needing a fragile equilibrium between technical expertise and ingenious methods. As we dive right into the strategies that can enhance both speed and performance in this domain name, the interaction between quality assurance measures and functional quality becomes an essential focal factor.

Understanding Bolt Kind

When selecting fasteners for a project, understanding the different types readily available is critical for making sure optimal efficiency and reliability. Bolts are used with nuts to hold products together, while screws are versatile bolts that can be used with or without a nut, depending on the application. Washers are crucial for dispersing the load of the bolt and protecting against damage to the material being fastened.

Selecting the Right Products

Recognizing the significance of choosing the appropriate materials is vital in making certain the optimal performance and reliability of the chosen bolt types talked about formerly. When it involves bolts and machining applications, the material selection plays a critical role in establishing the overall stamina, toughness, deterioration resistance, and compatibility with the intended environment. Different products supply varying buildings that can considerably affect the performance of the fasteners.

Usual materials made use of for fasteners consist of steel, stainless steel, brass, aluminum, and titanium, each having its distinct toughness and weaknesses. Steel is renowned for its high strength and longevity, making it suitable for a wide variety of applications. Selecting the ideal material includes taking into consideration elements such as toughness requirements, environmental problems, and budget plan constraints to make sure the wanted efficiency and longevity of the bolts.

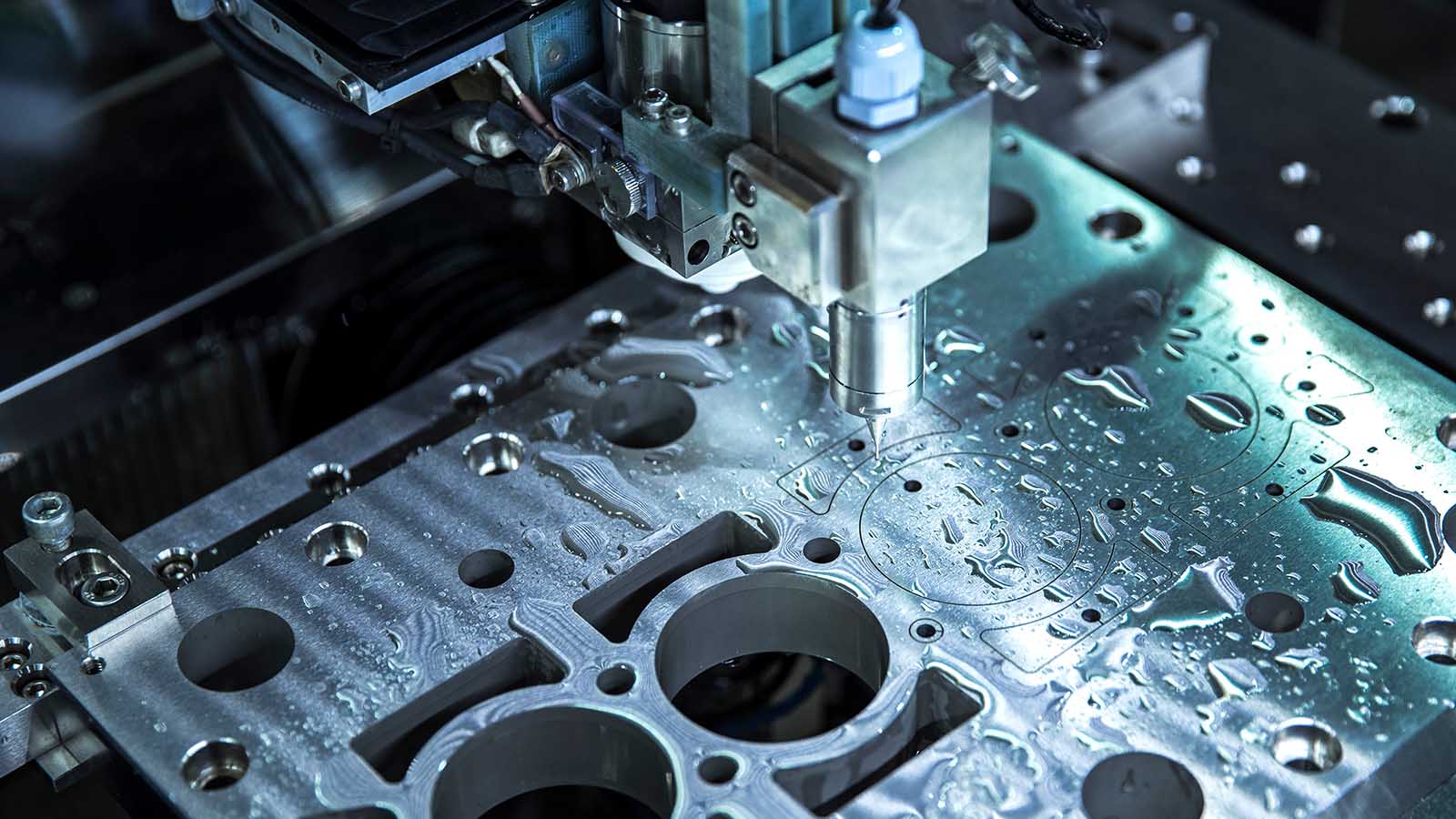

Precision Machining Techniques

Along with CNC machining, various other precision strategies like grinding, turning, milling, and boring play vital functions in bolt production. Grinding assists attain fine surface area finishes and limited dimensional resistances, while turning is often utilized to create round parts with accurate sizes. Milling and exploration operations are necessary for forming and creating holes in bolts, guaranteeing they meet exact specs and feature correctly.

Enhancing Speed and Effectiveness

To optimize fastener manufacturing processes, it is crucial to simplify operations and apply effective strategies that match precision machining methods. Automated systems can handle repeated jobs with precision and rate, allowing employees to concentrate on more complex and value-added tasks. By combining these methods, manufacturers can accomplish an equilibrium between rate and precision, eventually improving their affordable side in the fastener market.

Top Quality Control Steps

Applying strenuous high quality control steps is essential in ensuring the integrity and uniformity of fastener items in the manufacturing process. Fasteners and Machining. Quality click for info control actions include various phases, starting from the choice of raw materials to the last evaluation of the ended up bolts. This involves analyzing aspects such as material structure, durability, and toughness to ensure that the bolts meet sector standards.

Routine my blog calibration of tools and machinery is imperative to keep uniformity in production and make sure that fasteners satisfy the needed tolerances. Executing rigorous protocols for determining and attending to non-conformities or flaws is essential in preventing substandard products from getting in the marketplace. By developing an extensive high quality control structure, suppliers can support the track record of their brand name and supply bolts that meet the highest requirements of efficiency and longevity.

Conclusion

In the complex world of bolts and machining, the mission for precision and speed is a perpetual difficulty that demands precise attention to information and tactical preparation. When it comes to fasteners and machining applications, the product selection plays a crucial role in identifying the overall toughness, resilience, corrosion resistance, and compatibility with the intended environment. Accuracy machining entails different sophisticated techniques that guarantee the tight tolerances and specifications required for bolts.In addition to CNC machining, other accuracy strategies like grinding, turning, milling, and drilling play vital duties in bolt production.To optimize bolt production procedures, it is crucial to simplify operations and implement reliable methods that match precision machining strategies.

Report this page